In order to end the fashion and technology business model of short-life products in Europe, the European Commission (EC) has proposed a European Union eco-regulation to apply to energy-related products and expanding into electronics, textiles, furniture, cushions and tires...

Accordingly, new regulations require textiles entering the European market to have a long life, be reusable and repairable. To achieve this standard, manufacturers must use recycled, non-toxic, environmentally friendly fibers. At the same time, if the textiles are no longer usable, the manufacturer must be responsible for the recovery and recycling, minimizing the burning and burying of the products.

All of the above information must be provided to consumers by the manufacturer through a digital passport for each product. In addition, the European Union's ecological regulation also calls for fashion companies to reduce the number of collections each year.

With this proposal, the ecological standards applied to many types of goods, especially textiles, partly reflect the green consumption trend of the European market in general. In particular, fashion brands and garment enterprises doing business in the European market, including Vietnamese enterprises, need to update soon. With this regulation of the EC, Vietnam's textile and garment industry must change to meet the new ecological regulations for textiles and garments consumed in the EU.

Textiles are the industry with the fourth largest impact on the environment and climate change. The new strategy will therefore ensure textiles are produced more durable, repairable, reusable and recyclable, in order to quickly tackle fashion and textile waste.

Textile products must be made from as many recycled fibers as possible, contain no harmful substances and fully respect social rights, consumers will benefit from higher quality textiles that are more durable.

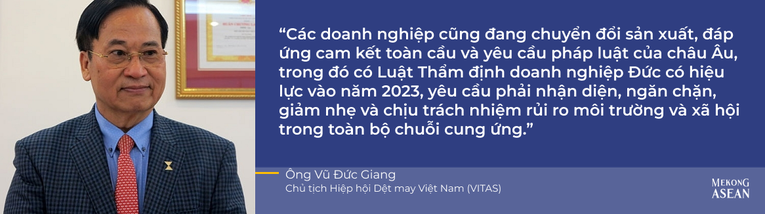

Sharing about this issue, Mr. Vu Duc Giang, Chairman of the Vietnam Textile and Apparel Association (VITAS), said that many enterprises in the supply chain of the textile and garment industry that process for major brands in the world are having to comply with the regulations. comply with related requirements "greening" in production

Currently, in the world market, especially the European market, the majority of Vietnamese textile and garment enterprises in the supply chain of the textile and garment industry outsourced to big brands have received the "greening" requirements. in production as well as implementing social and environmental responsibilities and reducing emissions...

Mr. Giang also emphasized that "greening" the textile and garment industry is a global trend that Vietnamese businesses must implement to achieve sustainable development goals and increase exports to major markets that have signed the Agreement. free trade (FTA). Especially the EU, which is an import market of about 4.5 billion USD of textile and garment goods from Vietnam (the peak year).

Target to reduce energy consumption for textile products

Not only the European market, many other major export markets of Vietnam's textile and garment such as the US, Japan, or South Korea also have regulations related to production processes that must be more environmentally friendly. such as related to the use of renewable energy, water conservation, or wastewater treatment.

Therefore, Vietnamese textile and garment enterprises are currently making efforts to change, towards "greening" production to meet requirements and maintain orders in major markets. Major fashion brands in the world - the ordering partners of Vietnam's textile and garment industry, also tend to prioritize ordering from "green" manufacturers that meet environmental conditions. Therefore, the pressure as well as the challenges posed to Vietnam's textile and garment export enterprises are not small.

According to the Vietnam Textile and Apparel Association (VITAS), the goal is that by 2023, textile enterprises that are members of the VITAS Sustainability Committee will reduce their energy consumption by 15% and water consumption by 20%. These are also criteria to evaluate competitiveness when participating in international supply chains.

Mr. Vuong Duc Anh, Chief of Office of the Board of Directors, Vietnam National Textile and Garment Group (Vinatex) said that businesses are now aware of this. Businesses also have to spend money to invest to meet the requirements of "greening" textiles, such as investing in rooftop electricity, investing in systems to save water or reusing water in factories. In particular, for manufacturers of jeans or textile dyeing houses, they will have to ensure that chemicals are safe to use, there must be a wastewater treatment process, to save maximum water in textile dyeing technologies, even do not use water.

"We are encouraging and calling on Vietnamese textile and garment enterprises to invest in equipment, technology as well as premises and factories to ensure that they can adapt to the requirements and requirements of the Law. Environment and saving energy and water resources set by international organizations; or building development programs, calling for investment in solar energy and renewable energy", said Mr. Vu Duc Giang, Chairman. Vietnam Textile and Apparel Association said.

Thu Trang

https://mekongasean.vn/det-may-viet-nam-huong-toi-tai-che-va-giam-thai-de-dap-ung-thi-truong-lon-post6913.html

mekongasean