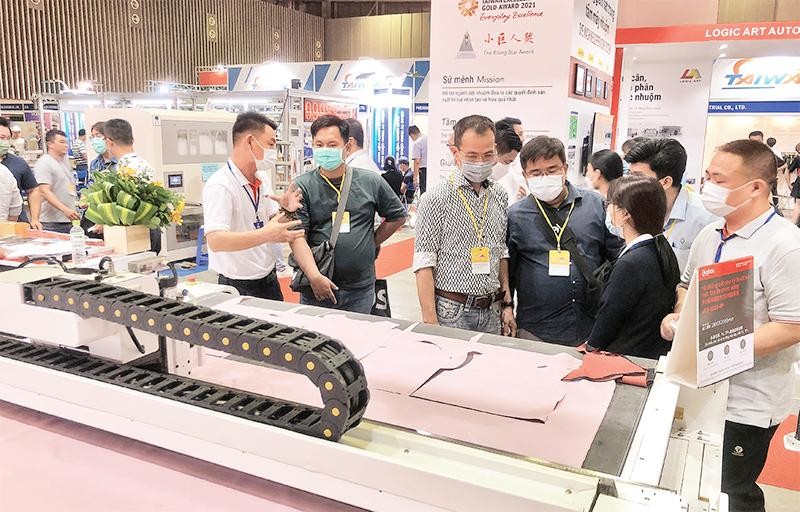

Textile enterprises visit and learn about modern machines to increase the value of products at the international exhibition of the textile industry - equipment and raw materials in Ho Chi Minh City.

Contrary to the prosperity in the first half of 2022 when textile and garment orders rushed, businesses worked through the night to keep up with the schedule, now, almost all activities are slowing down when the price of raw materials increases, output in many countries is increasing. The main export markets are congested. At Viet Thang Jean Co., Ltd (Thu Duc city), the working atmosphere is still rhythmic as workers continuously complete products for orders to be exported to the US and Europe. However, the company's General Director Pham Van Viet is still worried about the upcoming business months. "When the epidemic appeared, textile and garment enterprises faced difficulties in raw material supply; after the supply of raw materials was stable, enterprises faced difficulties in output. According to statistics, the export of textiles and garments to Europe , the US is decreasing from 30% to 40%; At the same time, the Japanese market will also reduce buying and is forecast to drop sharply in the first quarter of 2023. Faced with the above situation, many enterprises in the industry have to cut down their operations. production activities down to five sessions/week, the possibility of cutting down to three or four sessions/week in the near future," Mr. Viet said.

According to Deputy Director in charge of the Center for International Integration Support in Ho Chi Minh City Huynh Minh Vu, the consumption situation in some markets declined due to high inflation in major textile consuming markets such as the US. , EU... Besides, the complicated developments of the Russia-Ukraine conflict led to an increase in input materials in the textile industry. The risk of a re-emergence of the Covid-19 epidemic due to new strains is still present in many countries and around the world. Along with that, important trading partners of Vietnam such as China, Japan ... are still applying strict measures to combat the epidemic, greatly affecting the supply chain and consumption of textile products. Vietnam. Notably, the textile and garment industry was also affected by exchange rate fluctuations in export activities, labor shortage after the epidemic..., as well as requirements for traceability of cotton, fabric, yarn and green. textiles from a series of new generation Free Trade Agreements (FTAs). Sharing the same opinion, Deputy General Secretary of the Vietnam Textile and Apparel Association (VITAS), Head of VITAS Representative Office in Ho Chi Minh City, Ms. Nguyen Thi Tuyet Mai said: The textile industry is still facing challenges. such as lack of fabric, not active source of raw materials. Besides, enterprises in the industry are also export-oriented with the rate of about 80%, not focusing on the domestic market and not selling B2C (business model, used exclusively in the field of e-commerce); Textile and garment also do a lot of processing with the rate of 60%, FOB (price at the seller's border gate) about 25%-30%, ODM (original design manufacturer) about 9%. "In addition, the industry's logistics also face many difficulties such as lack of empty containers, high freight rates and dependence on shipping lines. Meanwhile, small and medium enterprises account for 80% of the industry, so they have limited access to capital to investment in transformation and investment in green production," said Ms. Mai.

In the face of continuing difficulties, in order to save themselves, textile and garment enterprises can only control input costs by continuing to invest in upgrading machinery and technology; carefully study the standards of the brand, the market demand for selective investment, not spread investment. Particularly, domestic enterprises, which have weak internal resources, can enter into joint ventures and link with other enterprises to expand their scale, be self-sufficient in production, and avoid relying too much on imported sources. In order for textile and garment enterprises to have more opportunities to expand the market to find partners, upgrade modern technology to meet the high requirements of FDI enterprises (foreign-invested enterprises), mid-week, In Ho Chi Minh City, an international exhibition of the textile industry - equipment and raw materials took place. Here, hundreds of types of modern machinery, equipment and accessories of many countries have been marketed to Vietnamese textile and garment enterprises; At the same time, partners from other countries also inquired about Vietnamese businesses asking for cooperation. Deputy Director of the Trade Promotion Department of the Ministry of Industry and Trade, Mr. Le Hoang Tai affirmed: Textile is one of the key industries of the country. This industry not only plays the role of an industrial production industry that brings high export value, but also contributes to stabilizing social security and creating jobs for workers. Currently, the textile and garment industry is employing about 2.5 million workers, the annual export turnover is about 40 billion USD, the average income of workers in the textile industry is about 3,800 USD/person/year. However, Mr. Tai said that although the export turnover of textiles and garments is high, the added value is still low, the industry has not been proactive in raw materials, has not met the upstream stages of the supply chain that bring high prices to customers. higher value added. Besides, labor productivity is also lower than other countries in the region, technology level is quite average. "Vietnam's textile and garment industry needs to strengthen development in depth instead of breadth, participate more deeply in the global textile and garment supply chain. In particular, focus on stages that bring high added value such as design and manufacturing. design, production of input materials and accessories, distribution, step by step moving to a higher position in the production chain", Mr. Tai emphasized.

Post and Photo: Phuong Vy

https://nhandan.vn/khoi-thong-xuat-khau-cho-nganh-det-may-post708348.html

nhandan