Microscopic contamination from textile products has become a global problem. Microplastics are any particles/fragments of plastic less than 5 mm in size. Contaminating the environment every day, microplastics contain or carry harmful chemicals that have negative effects on nature and human health, so the ingestion of microplastics through water or food such as fish or clams, is of particular concern.

One of the sources responsible for the release of microplastics into the environment is laundry. During the washing process, clothes shed microplastic fibers. These microplastic particles are neither captured by washing machines nor filtered during wastewater processing and as a result end up in rivers or oceans. Once these particles enter the aquatic environment, they interfere with the food chain, creating potential long-term risks for living organisms and the entire ecosystem.

With growing concern among government organisations, NGOs and consumers about the impact of the fashion industry on the environment, it is increasingly important for the industry to take serious action against microplastic pollution. become more important than ever.

At the time of this article, there were no industry standards or technical procedures for looking at microplastics shed from household washing. Eurofine Softlines & Leather has developed a method to quantify the lint shedding from clothes during household washing, and to identify the relationship between microplastic shedding and key clothing attributes such as fabric weight. and fiber composition, as a way to help the fashion industry better understand this key industry issue.

What are microplastics?

The unintentional release of microplastics into clean water and global ocean waters is a concern for human health and the environment, and has many potential risks such as reproductive harm, obesity and injury. organs are still not fully understood.

The term microplastics (in some cases the short term MP is used) refers to particles of polymeric material less than 5 mm in size. Depending on the source, microplastic particles are classified as either primary or secondary miroplastic.

Primary microplastics are plastics that are introduced directly into the environment in the form of small particles and are intentionally added to products, such as cosmetics, shower gels or toothpastes; or derived from the grinding of plastic objects during manufacture, use or maintenance, such as microplastics from tires or clothing in manufacturing and washing processes.

Secondary microplastics are derived after the degradation of large polymeric objects into smaller pieces of plastic when exposed to the environment. This process occurs under the influence of many environmental factors such as optical degradation, oxidation, humidity, temperature extremes etc. Some examples of secondary microplastics are microplastics from plastic waste, such as shopping bags, fishing nets or plastic cups.

In this paper, the quantitative analysis of microplastic shedding refers to primary microplastics.

Effects of microplastics on oceans and other aquatic environments

Plastic is an extremely popular material in our daily lives due to its versatile applications and uses. However, one of the properties of plastics in general is that its rate of biological degradation is very slow - it can take "decades" or even hundreds of years to decompose.

According to one study, 35% of primary microplastics found in the world's oceans can be attributed to synthetic laundry, while wheel wear while driving and urban dust account for 28% and 24% respectively. microplastics.

Although much research has been done to support this data, scientists are still investigating the origins of microplastics and, according to a recent study, microfibers in ocean water are mainly composed of natural polymers. The study found that 79.5% of the microfiber in ocean water is cellulose, 12.3% is of animal origin and 8.2% is of synthetic origin.

This data is important in terms of the growing demand for synthetic fibers and synthetic fiber production. Global synthetic fiber production has more than doubled in the last 20 years and this growth is estimated to continue over the next decade, reaching 145 million tons in 2030 if this trend is maintained.

62% of fiber production of the current 107 million tons of fiber globally is synthetic, with polyester being the most produced fiber, accounting for 51.5% of total fiber production.

In addition to microplatic pollution, several additional studies suggest that microplastics can act as carriers of toxic substances, such as organic pollutants (POPs) and heavy metals, when This hazardous substance adheres to the surface of microplastics when exposed to the environment.

While wastewater from industry and households is treated at a wastewater treatment plant to purify the water and to remove toxins before it returns to the water cycle, plants do not. Microplastics can be removed due to their extremely small size (<5 mm). Although this has been known for several years now, there has been no progress in fixing this problem.

As noted earlier, 35% of primary microplastics originate from washing clothes. During the storage and washing of textile garments, the fabric is subjected to mechanical stress and abrasion which causes fragmentation of the textile fibres, and as a result leads to the shedding of primary microplastics into the water. These shed microplastics are carried away by the water current and through the barriers of the wastewater treatment plant, entering various water bodies (aqueous areas).

Toxic substances and heavy metals stick to surface plastics and after reaching the ocean are digested as food by various marine species such as zooplankton. As a result, microplastics shed from clothes during washing enter the food chain and can eventually affect humans. While more research is needed, scientists believe that plastics being ingested by humans could have many negative outcomes. Effects can include liver damage, fertility problems, developmental delays in children, and chronic inflammation. Because of the biosustainability of plastics, the impact can be very long-lasting, and it may take a lot of effort to correct the problems we have been creating over the past two or three decades as a result of microplastic pollution.

No industry standardization and technical solutions

Despite the fact that microplastics present many hazards, there are no standards or requirements that evaluate or limit the amount of microplastics that a garment can release into the water during washing. In addition, the measurement of microplastics from textile sources has not been studied in depth to form standards or methods that will, on the one hand, assist in objective and quantitative assessment, and on the other hand, aid in the search for possible solutions. .

There are various technical solutions available on the market, however further research is needed to determine the efficiency and effectiveness not only in terms of retaining fibers or avoiding shedding into the water, but also on how to avoid this. change the properties of fabrics and clothing, or the efficiency of a wash cycle.

With regard to microplastic quantification, technical working groups on standardization and cross-industry agreements have recently been created to pursue the harmonized testing needed for the right assessment of the problem and investigation of options. viable options to tackle the global release of microplastics.

Eurofins Softlines & Leather has developed an in-house method that allows customers to quantify and characterize microplastics shed from clothing or fabrics by simulating household washing.

This test is built on a repeatable and reproducible methodology, and provides results after numerous tests and thorough internal review. The primary objective of the test is to quantify microplastic shedding during washing using standard and controlled conditions and parameters, thus providing information on the amount of microplastic shed during one or more cycles. washing cycle repeats.

Method Summary

The method can be used to quantify microplastic shed from fabric or clothing samples.

Prior to testing, samples were evaluated for basic textile properties, including composition, structure and weight.

Perform a simulated washing process using a sealed drum that rotates to create motion, simulating the mechanical action of a washing machine. The drum is also retrofitted with non-woven and non-polymeric materials, which simulate the wear caused during washing when the garment or fabric comes into contact with other garments during the wash cycle.

All water used in the washing process is collected from the drum for filtration, and all particles suspended in the solution are collected. For filtration, we use standard and certified filters, available in different pore sizes; This helps to segment the size bands of particles that fall off during washing.

This method can classify shedding by different size ranges and also provides information on extrapolating shedding by unit (i.e. garment), by weight or by weight. surface. These three parameters are important to get an accurate picture of the actual microplastic shedding, since clothing is produced in large volumes.

In addition, using the most modern analytical techniques, SEM microscopy, FTIR and Raman spectroscopy and chemical analyses, we are able to identify the fiber type, providing additional data to our customers. row.

Quantitative analysis results of microplastic shedding

The results below are after analysis of 598 samples received. All samples shed microplastics with different intensities. The analysis observed four key factors and their correlation with microplastic shedding:

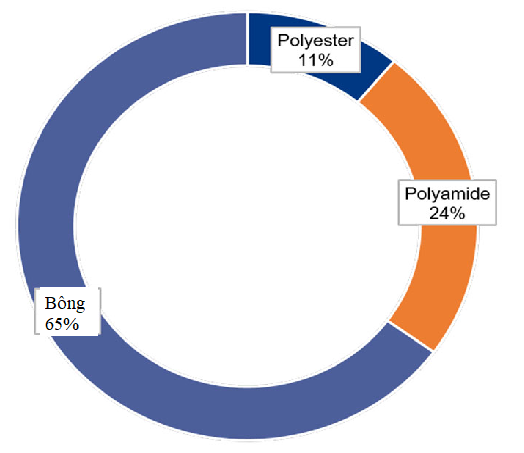

Figure 1 – Lint shed from different fabrics

The analysis shown in figure 1 shows the response of different fiber samples after one wash, namely the total particles dropped into the water, expressed in milligrams of particles per kilogram of fabric.

As part of our study, we also took a close look at a few common assumptions about microlplastic shedding and came up with the following findings:

Characterization of microplastic shedding

For all the tests carried out, Eurofins classified and studied both the particle size and the microplastic shedding in different samples and by different pore sizes.

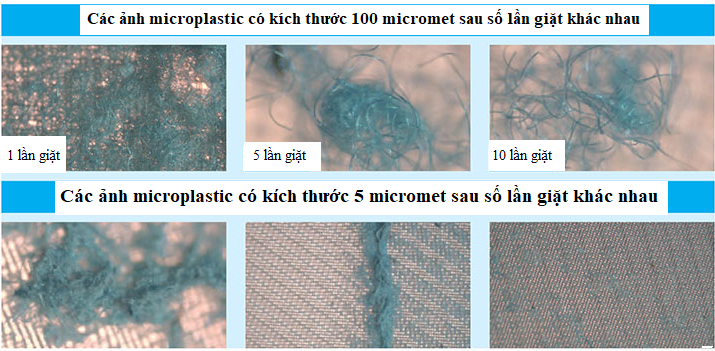

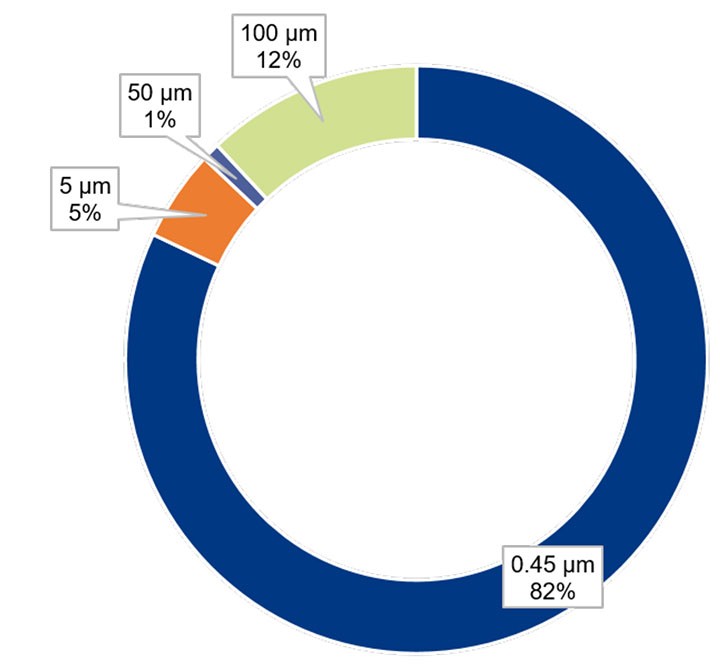

Figure 2 – Length of fibers shed xơ

The results show that the fabrics release fibers of different sizes, with lengths ranging from 0.45 µm to > 500 µm (as determined using different pore sizes).

The results showed that a greater amount of fibers shed were in the range of 0.45 µm to less than 50 µm in length, and were shed in about 1 to 10 wash cycles.

After 10 wash cycles, some samples showed a slight increase in the release of larger particles, even the greatest percentage of fiber shedding can still be assumed to be fibers in the range of 0 length. 45 µm to less than 50 µm (figure 2).

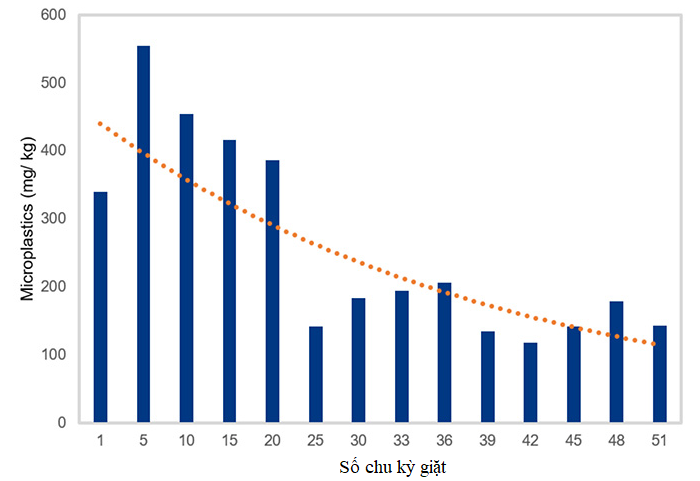

We also look at the amount of microplastics and particles that fall off during multiple wash cycles. Data from all samples tested for multiple washes and drying (natural drying) indicate that the amount of microplastics and particles released by the samples tends to decrease after multiple wash cycles. We observed that the majority of the release of micro and microplastic particles occurred during the first 20 washing cycles (of the sample fish studied).

Figure 3 – Microplastic released from woven polyester fabric after several washing and drying cycles

The textile industry as well as the polymer-related industries are at the forefront of new environmental challenges that will require interested parties in the supply chain to collaborate to minimize the risk of microplastics. to ourselves, to future generations and to our environment.

Standards and methods for assessing the impact of microplastics and most importantly solutions need to be put in place early by intense effort at every step of the supply chain – from manufacturing products that are more durable and sustainable. better resistance to fibrous shedding to reducing the amount of microplastics that reach water bodies (where water is stored).

Eurofins Softlines &Leathers offers a complete suite of solutions that each purchasing organization and supplier will require throughout the textile and footwear supply chain. Through our Technical Centers in Spain and the UK and laboratories in Asia, Europe and the US, sustainable solutions, testing services as well as legal and compliance services us that we can assist customers to ensure their product quality and compliance. We participate in various industry organizations and associations that lead product safety and compliance in various parts of the world, and will join and technical working groups devoted to standardization and interdisciplinary agreements on microplastics.

References

1.GESAMP (2015), “Sources, fate and effects of microplastics in the marine environment: a global assessment” (Kershaw, P. J., ed.), (IMO/FAO/UNESCO-IOC/UNIDO/WMO/IAEA/UN/UNEP/UNDP Joint Group of Experts on the Scientific Aspects of Marine Environmental Protection), Rep. Stud. GESAMP No. 90, 96 p.

2. Ioakeimidis, C. et al., “The degradation potential of PET bottles in the marine environment: An ATR-FTIR based approach,” Sci. Rep. 6, 23501; doi: 10.1038/srep23501 (2016).

3. Boucher, J. and Friot D. (2017), “Primary Microplastics in the Oceans: A Global Evaluation of Sources,” Gland, Switzerland: IUCN. 43pp.

4. Suaria et al., Sci. Adv. (2020), “Microfibers in oceanic surface waters: A global characterization,” DOI: 10.1126/sciadv.aay8493.

5. Preferred Fiber & Materials Market Report 2019, Textile Exchange.

6. F Yu, C Yang, Z Zhu, X Bai, J Ma (2019), “Adsorption behavior of organic pollutants and metals on micro/nanoplastics in the aquatic environment,” Science of The Total Environment 694, 133643.

7. Environ. Sci. Technol. 2013, 47, 12, 6646–6655 (2013), https://doi.org/10.1021/es400663f.

https://vinatex.com.vn/12325-2/

Source: vinatex.com.vn