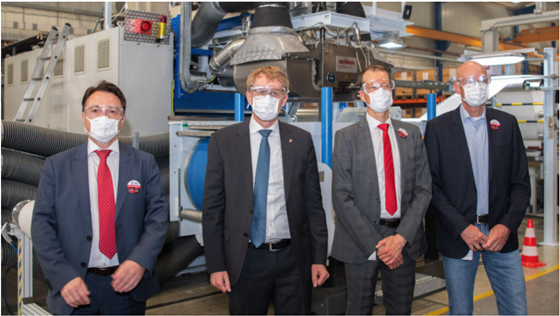

Daniel Günther (second from left), Premier of Schleswig-Holstein, together with Rainer Straub, Chief Oerlikon Nonwoven, Matthias Pilz, Head of Oerlikon Neumag, and Matthias Wäsch, Chairman of the Construction Council, at the Neumünster presentation on Oerlikon meltblown nonwovens production technology. (Photo: Oerlikon)

Since the onset of the COVID-19 pandemic, demand for masks and protective clothing worldwide has resulted in new orders for the Swiss Oerlikon Nonwoven business unit of the Oerlikon Group.

From the site of the manufacturing facility in Neumünster, Germany, the ecuTEC + patented high-tech meltblown systems and their generator nonwovens technology are being exported worldwide for the first time. have contracts signed with businesses in Australia.

Before the presentation, Oerlikon shared "Daniel Günther - Premier of Schleswig-Holstein, won at the technology website by a global review company". Rainer Straub, Director of Oerlikon Nonwoven happily commented “The machinery and systems for the production of man-made fiber solutions and nonwovens from Neumünster is an outstanding brand worldwide. Especially during this crisis, technology from the state of Schleswig-Holstein proved to be world class.

In addition to a tour of the meltblown system and assembly and manufacturing facilities, Premier Daniel Günther's visit had a above all the purpose of dialogue between politicians and business.

Oerlikon.

Rainer Straub, Head of Oerlikon Nonwoven, and Matthias Pilz, Head of Division Oerlikon Neumag, both thanked the Oerlikon firm for its many fortunate experiences in the state of Schleswig-Holstein over the years and hopes for success. cooperation in the future.

“This is the result of our additional investment in Neumünster supported by the Government, which includes a new technology hub to be completed by the end of the year as well as a logistics center already in operation. As one of the largest employers in the region, we are stepping up growth, focusing on both fostering industry and business and fostering an effective training and education system, for Innovation process can only be successful when there is an excellent team of engineers ”, shared Matthias Pilz.

Rainer Straub made a special appeal to the Premier, “Consider education and training as a top priority. This will ensure the future of Schleswig-Holstein state become a center of research and production excellence ”.

Program to digitize five million euros

Daniel Günther, the current Premier of the Schleswig-Holstein state since 2017, after consulting with one of the Federal State's current training initiatives, immediately replied: “The government is supporting institutions of higher education and students in the current Covid crisis. With a 5 million euro digitization program we are investing in long term digitization at our higher education institutions. With this, we are creating a future for the younger generation, especially those who are most likely to continue inventing the next generation of man-made fiber systems.

According to Oerlikon, the Premier was impressed by the willingness that Oerlikon has provided at a high level since the onset of the COVID-19 pandemic in order to master the current challenges it has implemented when it implemented meltblown technology. .

Rainer Straub explained: “When the pandemic started in February, the demand for masks increased rapidly, and we at Oerlikon Nonwoven responded immediately. We have strengthened all of our manufacturing capacities, using the existing laboratory system at Neumünster to rapidly manufacture nonwovens for masking. As a result we were able to make a small regional contribution to meeting demand. In addition, we have drawn limitations in order to improve our skills in building operating systems and machines to cater to the expectation of meeting the global demand for meltblown systems as quickly as possible. .

Leading melblown technology

Oerlikon Nonwoven said that meltblown technology is a non-woven fabric production technology used to produce market-recognized pages, and is the most technically effective method for producing high-separation filter materials made from plastic fibers. . The manufacturing capacity of respirators available in Europe so far has been mainly produced on Oerlikon nonwovens, the company added.

“Producers in many countries are hoping to reduce reliance on imports. Therefore, what we are experiencing in Germany is happening in both industrialized and emerging countries around the world, ”commented Rainer Straub.

In addition to China, Turkey, the United Kingdom, Korea, Austria and many countries in both North and South America, Australia and Germany, will be one of the first countries where Oerlikon Nonwoven will supply machinery and equipment. before the end of 2021.

https://vinatex.com.vn/nhu-cau-toan-cau-ve-cong-nghe-meltblown-cua-oerlikon-tang-vot/

Source: vinatex.com.vn